If you are working on a new printed circuit board design, you need accurate cost and design estimates before moving to production. A PCB calculator makes this process simple by instantly providing details such as board cost, trace width, and material requirements. Instead of waiting for manual quotes from manufacturers, you can input your specifications and receive immediate results. This helps designers, students, and businesses save both time and money while ensuring that their PCB layout is optimized from the start.

Try the free PCB Calculator by Megabyte Circuit Systems to get instant estimates for your design.

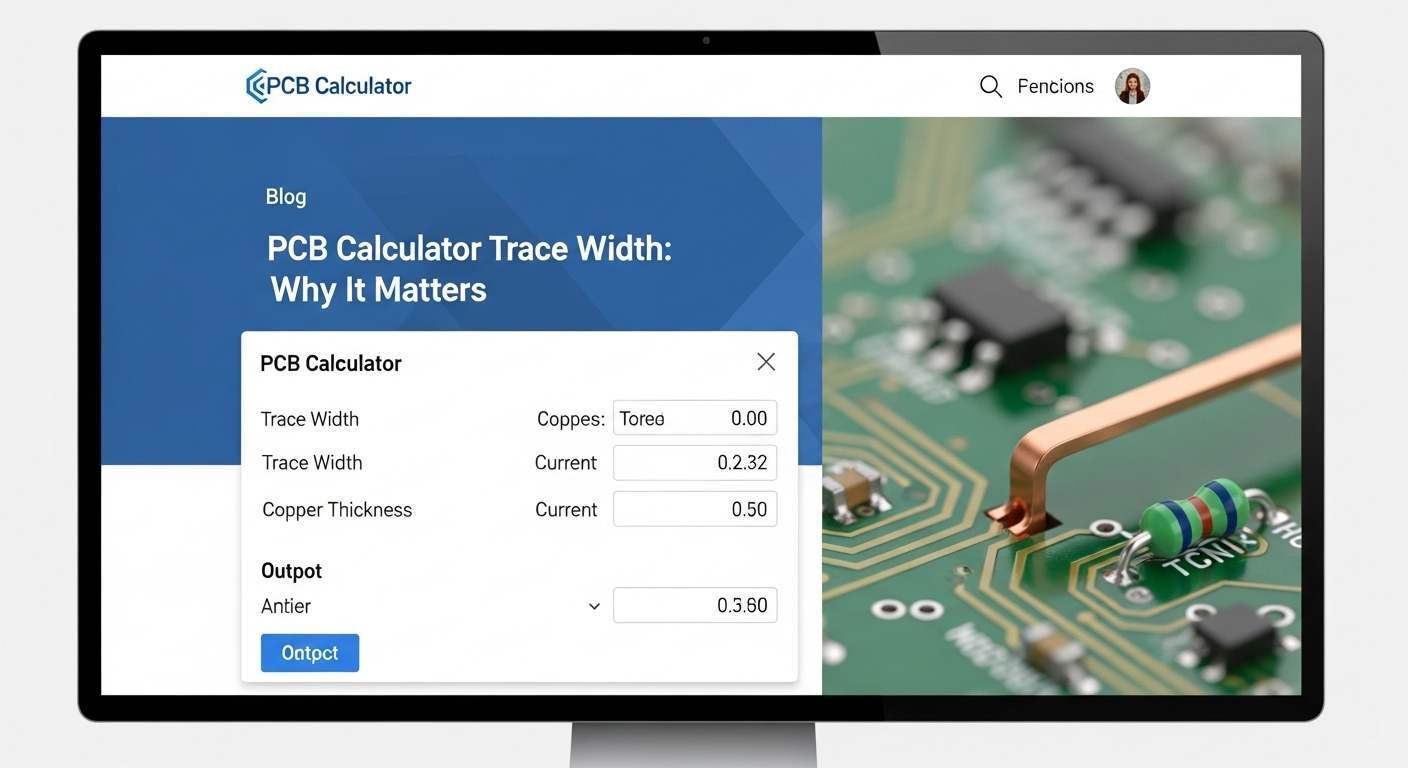

A PCB calculator is an online tool that allows you to calculate essential parameters for your circuit board. These include the manufacturing cost, required trace width, current capacity, percentage tolerances, and other design factors. By entering basic inputs such as dimensions, number of layers, thickness, and copper weight, you can instantly determine whether your design is practical and within budget.

Unlike manual calculations or waiting for vendor responses, PCB calculators give you results in seconds. This makes them highly valuable for anyone working in electronics from students building DIY projects to engineers designing advanced multilayer boards.

At Megabyte Circuit Systems, our PCB calculator is designed to be fast, accurate, and beginner-friendly, making it a trusted tool for PCB enthusiasts and professionals.

PCB manufacturing involves many variables, and costs can vary significantly based on board specifications. A calculator helps in three key areas:

By having reliable estimates, you can confidently plan your project budget and timelines.

Most calculators require a few simple inputs to generate results. The most common parameters include:

The tool processes these values and provides an estimated cost along with expected delivery timelines.

In addition to cost, designers often need to calculate the correct trace width to handle a given current. Using a PCB trace width calculator helps determine how wide copper traces must be to prevent overheating or signal loss.

For example, if your circuit carries 2A of current on an external layer with standard copper thickness, the calculator will suggest the minimum trace width required. This ensures safety, reliability, and compliance with IPC standards.

At Megabyte Circuit Systems, we’ve integrated trace width calculations into our PCB calculator so you can estimate both costs and performance in one place.

Trace width directly impacts how well your PCB performs. If the width is too narrow, the trace may overheat, leading to circuit failure. If it is unnecessarily wide, you might waste board space and increase manufacturing costs.

A PCB calculator trace width function balances these concerns by using formulas that consider current load, copper thickness, and allowable temperature rise. This ensures your board layout is both cost-efficient and safe.

Another useful feature is the PCB percentage calculator, which is often used for checking tolerances in component placement, copper coverage, or resistance values. Small variations can affect circuit performance, especially in high-frequency applications. A percentage calculator gives quick insight into acceptable design margins and helps engineers fine-tune their layouts.

By integrating percentage-based checks with cost and trace width calculations, designers get a complete picture of their board’s performance and feasibility.

Consider a designer creating a two-layer board for a power supply project. They input the following into the PCB calculator:

The calculator provides an estimated cost and turnaround time. Next, the designer uses the trace width calculator to check that the power traces can safely handle 3A of current. Finally, the percentage calculator confirms that copper fill tolerances remain within acceptable limits.

In less than five minutes, the designer has a clear view of cost, manufacturability, and performance without sending a single email to a manufacturer.

Save time and reduce errors with the Megabyte Circuit Systems PCB Calculator.

Using a calculator brings several advantages:

While PCB calculators are useful, they do have some limitations:

Despite these limitations, calculators remain one of the best starting points for PCB planning.

They are reliable for initial estimates, but final manufacturer quotes may differ based on order quantity, finish type, and shipping.

Yes, most tools allow up to 8 or more layers.

Usually, they focus on bare board manufacturing. Assembly requires a separate quote.

Yes, most online calculators are free to access and use.

A cost calculator estimates manufacturing price, while a trace width calculator ensures your design can handle required current safely.

A PCB Calculator is a vital tool for anyone involved in electronics design. From cost estimation to trace width calculations and percentage tolerance checks, it simplifies the planning process and ensures that designs are both practical and affordable.

By using such tools, you not only save time but also gain confidence that your board will perform as expected once manufactured. Whether you are a student, hobbyist, or professional engineer, integrating a PCB calculator into your design workflow can make the difference between success and costly mistakes.

Get started today with the Megabyte Circuit Systems PCB Calculator and see how simple PCB planning can be.

C/10, Yogeshwar Estate, B/H Madhuram Estate, Nr. Vishala Estate, Sardar Patel Ring Rd, Odhav, Ahmedabad, Gujarat, Ahmedabad - 382430, Gujarat (India)

Copyright © 2025. Megabytes Circuit Systems All rights reserved.

Powered by FrogMEE Tech