In today’s electronics industry, complexity and speed go hand in hand. Multilayer printed circuit boards (PCBs) have become a cornerstone of high-performance electronics due to their ability to deliver compact designs with robust functionality. As demand grows for faster product cycles and higher reliability, manufacturers require multilayer PCB services that combine speed with precision.

Megabyte Circuit System has emerged as a trusted leader in delivering fast and reliable multilayer PCB manufacturing services in India. With cutting-edge technology, skilled engineers, and strict quality controls, we ensure every multilayer PCB we produce meets the highest standards. This article explores what multilayer PCBs are, why speed and reliability matter, the manufacturing challenges, and how our expertise makes a difference.

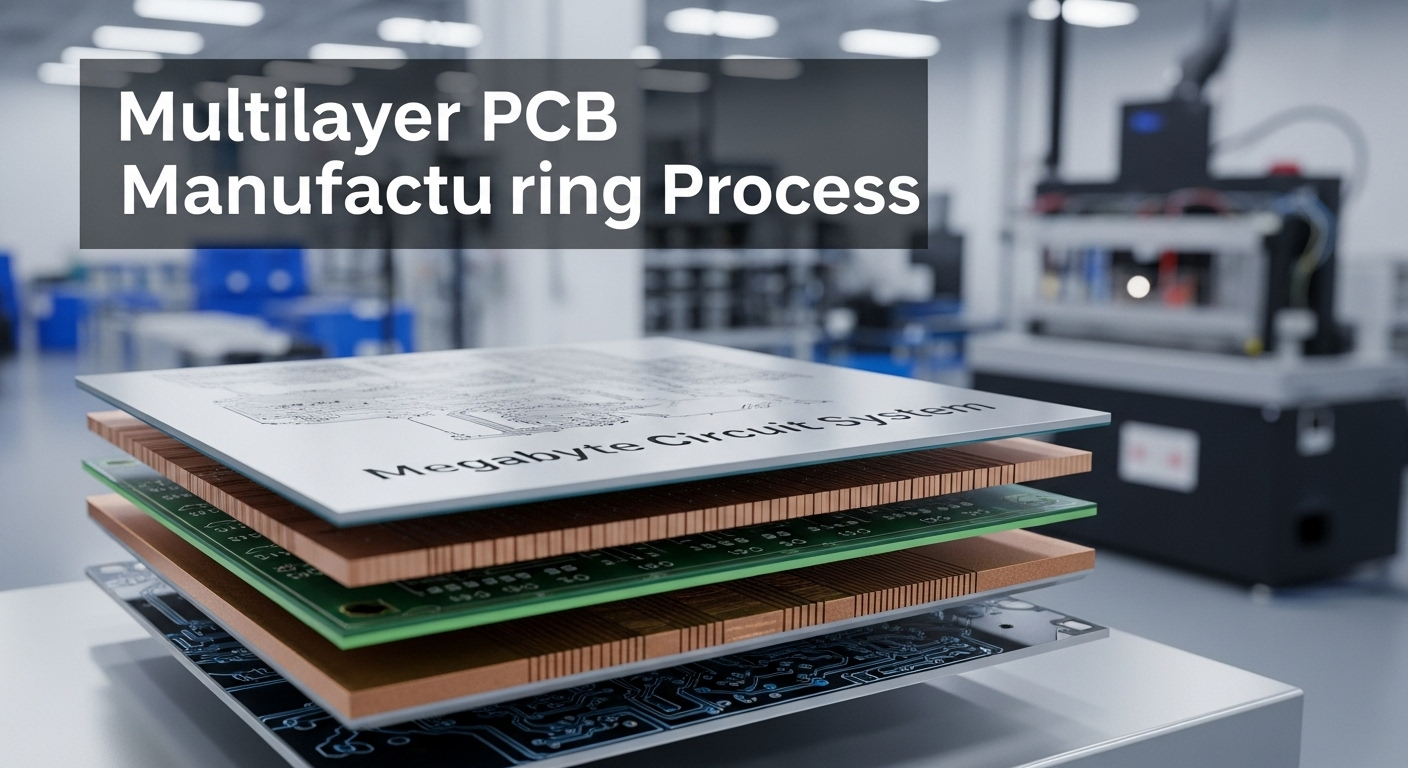

A multilayer PCB is a printed circuit board composed of three or more conductive layers separated by insulating material. These additional layers allow designers to accommodate more circuits, enabling compact designs and high-speed signal transmission without compromising performance.

Unlike single-layer or double-layer PCBs, multilayer boards allow for complex routing and higher density connections, making them essential in advanced electronics. Typical designs include 4-layer, 6-layer, and even higher-layer boards tailored to specific performance needs.

Multilayer PCBs are widely used in industries such as telecommunications, aerospace, medical electronics, automotive control systems, and consumer electronics. Applications range from smartphones and laptops to sophisticated control systems and defense electronics, all requiring compact designs, reliability, and exceptional performance.

In electronics manufacturing, time is a competitive advantage. Fast multilayer PCB manufacturing reduces time-to-market, allowing businesses to iterate designs and deliver products faster. Speed in manufacturing doesn’t just mean quicker delivery; it means rapid prototyping, accelerated production cycles, and timely product launches.

Reliability is equally critical. Multilayer PCBs often handle complex signals and higher frequencies. Any flaw in manufacturing can result in product failure, signal degradation, or costly recalls. For industries such as aerospace, medical equipment, and automotive electronics, reliability isn’t optional, it’s essential.

Megabyte Circuit System understands these demands. Our processes ensure quick turnaround without compromising quality. By leveraging advanced machinery, precise layer alignment techniques, and stringent quality control, we deliver multilayer PCBs that meet both timeline and performance requirements.

Whether you are building prototypes or full-scale production runs, our service ensures that your project stays on track while meeting the highest reliability standards.

Manufacturing multilayer PCBs involves a range of technical challenges:

At Megabyte Circuit System, we address these challenges with specialized expertise. Our engineers use advanced design verification tools and manufacturing processes to ensure that each board meets stringent performance criteria while being delivered quickly.

Megabyte Circuit System offers comprehensive multilayer PCB manufacturing services tailored to diverse needs. Our capabilities include:

Our robust infrastructure allows us to handle both small batch prototypes and large-scale production efficiently without compromising quality.

Selecting Megabyte Circuit System comes with multiple advantages:

Our services ensure you receive a high-quality multilayer PCB that meets your performance expectations and delivery schedules.

Our process is designed for speed and reliability:

Every step is executed with attention to detail to deliver boards that perform flawlessly in their intended applications.

Our multilayer PCB manufacturing services are critical for industries where precision and speed matter:

Each of these industries relies on multilayer PCBs to meet demanding performance and safety standards, making fast and reliable manufacturing essential.

Megabyte Circuit System has delivered successful multilayer PCB projects for clients across industries. For example, an IoT solutions provider needed a 6-layer PCB prototype within a tight schedule. Our team completed design review, manufacturing, and testing in record time, ensuring the client’s project launch stayed on track.

Another success story involved an automotive electronics firm that required high-reliability multilayer PCBs. Our precision manufacturing and thorough quality assurance helped the client meet their stringent safety standards and production deadlines.

These examples reflect our commitment to delivering speed and reliability without compromise.

In a competitive electronics industry, speed and reliability in multilayer PCB manufacturing are vital for success. Megabyte Circuit System delivers both with precision engineering, advanced manufacturing, and dedicated client support.

If you’re looking for a partner who can deliver fast and reliable multilayer PCB manufacturing services in India, contact us today for a consultation or quote. Let’s transform your PCB design into a high-performance product that meets your timelines and quality expectations.

C/10, Yogeshwar Estate, B/H Madhuram Estate, Nr. Vishala Estate, Sardar Patel Ring Rd, Odhav, Ahmedabad, Gujarat, Ahmedabad - 382430, Gujarat (India)

Copyright © 2025. Megabytes Circuit Systems All rights reserved.

Powered by FrogMEE Tech