In the realm of electronics, designing efficient printed circuit boards (PCBs) is critical for ensuring optimal performance and reliability. One key aspect of this process is understanding and minimizing power loss, which can significantly impact a circuit’s efficiency, thermal performance, and longevity. PCB power loss calculation involves quantifying energy dissipation in a PCB due to resistive, dielectric, and other losses. By mastering these calculations, engineers can create high-performance designs that meet the demands of modern applications, from consumer electronics to aerospace systems.

This guide delves into the technical aspects of PCB power loss calculation, offering a clear explanation of the underlying principles, formulas, and tools like PCB design calculators. We’ll explore best practices for minimizing losses and provide practical insights for engineers aiming to optimize their designs.

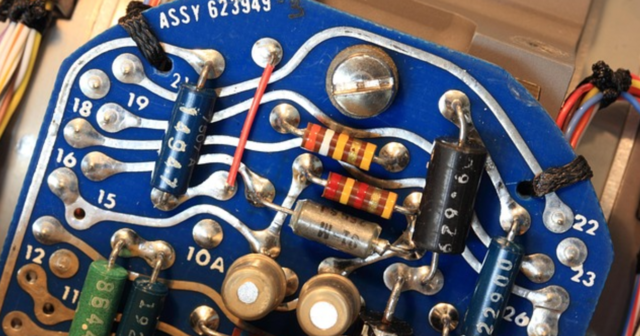

Power loss in a PCB occurs when electrical energy is converted into heat or other forms of energy, reducing the efficiency of the circuit. These losses primarily stem from three sources: resistive losses in copper traces, dielectric losses in the PCB substrate, and parasitic losses due to components or layout inefficiencies. Each type of loss affects the performance of high-speed or high-power circuits, such as those in 5G infrastructure, electric vehicles, or medical devices.

Resistive losses, often the most significant, occur due to the resistance of copper traces and vias. Dielectric losses arise from the insulating material’s interaction with high-frequency signals, while parasitic losses result from unintended capacitances or inductances in the layout. By calculating and mitigating these losses, engineers can improve signal integrity, reduce heat generation, and extend the lifespan of the PCB.

Accurate PCB power loss calculation is essential for several reasons. First, excessive power loss leads to heat buildup, which can degrade components, reduce reliability, and necessitate costly cooling solutions. Second, power loss impacts energy efficiency, a critical factor in battery-powered devices like wearables or IoT modules. Finally, in high-frequency applications, such as telecommunications, power loss can distort signals, leading to data errors or performance degradation.

For example, in a real-world scenario, a startup designing a drone’s control system found that unoptimized trace widths caused 15% higher power loss, reducing flight time. By recalculating and adjusting their PCB design, they improved efficiency and extended battery life by 20%. Such outcomes highlight the importance of precise power loss calculations in achieving efficient circuit designs.

To calculate power loss effectively, engineers must focus on the primary contributors: resistive, dielectric, and parasitic losses. Below, we explore each in detail to provide a foundation for accurate calculations.

Resistive losses occur when current flows through copper traces, which have inherent resistance. The power loss due to resistance is governed by Joule’s Law, expressed as:

[ P = I^2 \cdot R ]

Where ( P ) is the power loss (in watts), ( I ) is the current (in amperes), and ( R ) is the resistance (in ohms). The resistance of a trace depends on its material, length, width, and thickness, calculated as:

[ R = \rho \cdot \frac{L}{A} ]

Where ( \rho ) is the resistivity of copper (approximately ( 1.68 \times 10^{-8} , \Omega \cdot m )), ( L ) is the trace length, and ( A ) is the cross-sectional area (width × thickness). For high-current designs, wider and thicker traces reduce resistance and, consequently, power loss.

Dielectric losses occur in the insulating material (e.g., FR-4, Rogers) between conductive layers, especially at high frequencies. These losses are quantified using the dissipation factor (Df) and are calculated as:

[ P_d = \pi \cdot f \cdot C \cdot V^2 \cdot \tan \delta ]

Where ( P_d ) is the dielectric power loss, ( f ) is the signal frequency, ( C ) is the capacitance, ( V ) is the voltage, and ( \tan \delta ) is the dissipation factor. Materials with lower dissipation factors, such as Rogers substrates, are preferred for high-frequency applications to minimize dielectric losses.

Parasitic losses arise from unintended capacitances and inductances in the PCB layout, such as those caused by closely spaced traces or vias. These losses are harder to quantify but can be estimated using simulation tools. Proper layout techniques, like maintaining adequate trace spacing and optimizing via placement, help reduce parasitic effects.

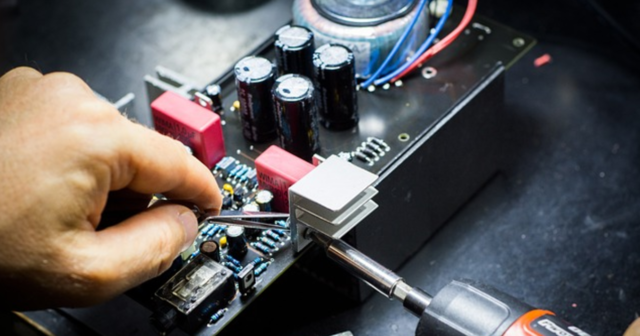

Manually calculating power loss can be complex, especially for multilayer PCBs with intricate layouts. Fortunately, PCB design calculators and software tools simplify the process by automating calculations and providing actionable insights.

Online PCB design calculators allow engineers to input parameters like trace width, length, current, and material properties to estimate power loss. Popular tools include:

These tools provide quick estimates, enabling engineers to iterate designs efficiently. For example, a designer can use the Saturn PCB Toolkit to determine that a 10-mil trace carrying 2A results in 0.5W of power loss, prompting a switch to a wider trace.

Advanced simulation software, such as ANSYS HFSS or Cadence Sigrity, models power loss in high-frequency or complex PCBs. These tools analyze resistive, dielectric, and parasitic losses across the entire board, offering detailed visualizations of loss distribution. While more expensive, they are invaluable for high-stakes projects like aerospace or telecommunications.

Reducing power loss is a critical step in achieving efficient PCB designs. Below are proven strategies to optimize your circuit and minimize energy dissipation.

To reduce resistive losses, design traces with appropriate width and thickness based on current requirements. For high-current paths, use wider traces or increase copper thickness (e.g., 2 oz/ft² instead of 1 oz/ft²). Shortening trace lengths by optimizing component placement also lowers resistance. For example, in a power supply PCB, repositioning a regulator closer to the load reduced trace length by 20%, cutting power loss by 10%.

Choose PCB substrates with low dissipation factors for high-frequency designs. While FR-4 is cost-effective for standard applications, materials like Rogers RO4003C offer lower dielectric losses for RF circuits. Consult with your manufacturer to balance performance and cost. A telecommunications company reported a 15% reduction in signal loss by switching to a low-loss substrate for their 5G base station PCBs.

In multilayer PCBs, dedicate entire layers to power and ground planes to reduce resistance and improve current distribution. This approach minimizes voltage drops and enhances signal integrity. For instance, a 4-layer PCB with a dedicated ground plane reduced power loss by 12% compared to a 2-layer design in a medical imaging device.

Careful layout design can reduce parasitic losses. Maintain adequate spacing between high-speed signal traces to prevent crosstalk, and use vias strategically to avoid unnecessary inductance. Simulation tools can help identify parasitic hotspots before fabrication. A case study from an IoT startup showed that optimizing via placement reduced parasitic losses by 8%, improving device reliability.

Excessive power loss generates heat, which can degrade performance. Incorporate thermal vias, heat sinks, or copper pours to dissipate heat effectively. For high-power designs, consider active cooling solutions like fans. A drone manufacturer used thermal vias in their motor control PCB, reducing operating temperatures by 10°C and extending component life.

PCB power loss calculation is critical in various industries. For example:

These examples demonstrate how precise power loss calculations lead to better performance and competitive advantages.

To integrate power loss calculations into your design process:

At Megabyte Circuit System, we specialize in designing and fabricating efficient PCBs tailored to your needs. Our team uses advanced PCB design calculators and simulation tools to minimize power loss and ensure high performance. Whether you’re developing a prototype or scaling to production, we’re here to help. Contact us for expert PCB design services.

PCB power loss calculation is a cornerstone of efficient circuit design, enabling engineers to create reliable, high-performance electronics. By understanding resistive, dielectric, and parasitic losses, and using tools like PCB design calculators, you can optimize your designs for minimal energy dissipation. Best practices, such as optimizing trace geometry, selecting low-loss materials, and implementing power planes, further enhance efficiency.

As industries like electric vehicles, 5G, and medical devices demand ever-higher performance, mastering power loss calculation gives you a competitive edge. Start optimizing your PCBs today and unlock the full potential of your designs. Request a quote for PCB fabrication services to partner with us and achieve superior circuit efficiency.

C/10, Yogeshwar Estate, B/H Madhuram Estate, Nr. Vishala Estate, Sardar Patel Ring Rd, Odhav, Ahmedabad, Gujarat, Ahmedabad - 382430, Gujarat (India)

Copyright © 2025. Megabytes Circuit Systems All rights reserved.

Powered by FrogMEE Tech